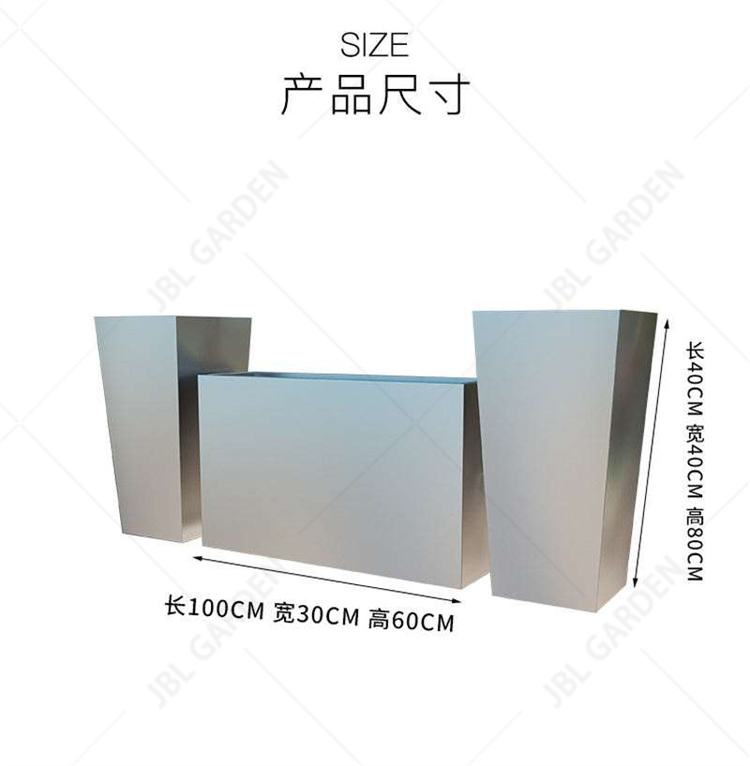

Stainless Steel Flower Planter

Great way to bring the outdoors into your space. Plant pots are perfect for growing succulents, grass, and small plants.

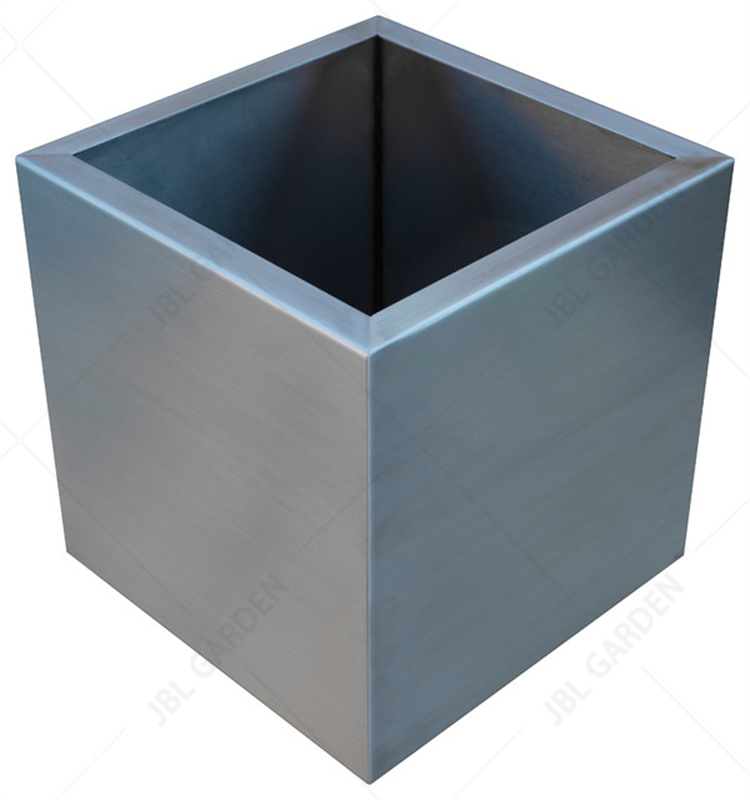

Contemporary Industrial Style - Stainless steel Flower Planter fits into any home décor with the simple shape and stainless steel material.

Included (4) low profile rubber pads - Easy to install, provides increased stability, and protects metal plant pots and the surface that you place it on.

The Stainless Steel garden pots helps you bring home a clean and sleek designer look. Perfect on the window sill, counter top, Fireplace mantle, and as a table's centerpiece. The heavy duty stainless steel is hand welded to ensure a water tight enclosure.

* EASY TO CLEAN: Like most stainless steel, finger prints and water spots may show. Simply use a damp towel, or a little window cleaner will take care of it. The plants depicted in the picture are not included with the purchase.

We also offer other steel materials,like Corten Steel Flower Planter,galvanized steel flower pots.

Stainless Steel Flower Planter,Garden Plant Pots,Flower Pot Holder,Metal Plant Pots

Henan Jinbailai Industrial Co.,Ltd , https://www.gardensteelarts.com